Technological process of screen printing glass(Part 1)

Jul. 21, 2020

Screen printing glass is a kind of decorative glass that uses a glass screen printing process to perform decorative printing on the glass surface and then fired at high temperatures.

Glass screen printing is the use of screen printing plates and glass glazes for decorative printing on glass products. Glass glaze is also called glass ink and glass printing material. It is a paste printing material made by mixing and stirring coloring material and connecting material. The coloring material is composed of inorganic pigments and low-melting flux (lead glass powder); the linking material is commonly known as leepan oil in the glass screen printing industry. After printing, the glass products should be fired at a temperature of 520~600℃ in the furnace, and the glaze printed on the glass surface can be consolidated on the glass to form a colorful decorative pattern. If screen printing is used in combination with other processing methods, more ideal results will be obtained. For example, processing the glass surface before or after printing by methods such as polishing, engraving, and corrosion can double the printing effect.

How is silk screen glass produced? The glass printing mesh supplier will tell you about the specific process flow of screen printing glass. Stretching net → sizing → drying → plate printing → developing → drying ↓ flat glass → cutting → edging → cleaning and drying → printing ↓ sintering, although watching The process is quite simple, but there are many places to be noted in the specific operation:

1. The glass suitable for printing cuts the glass according to the user's requirements. It can be in a regular shape or an irregular shape, and then it is ground and processed by grinding, then washed and dried for use. Special care should be taken here that there are no watermarks on the glass surface.

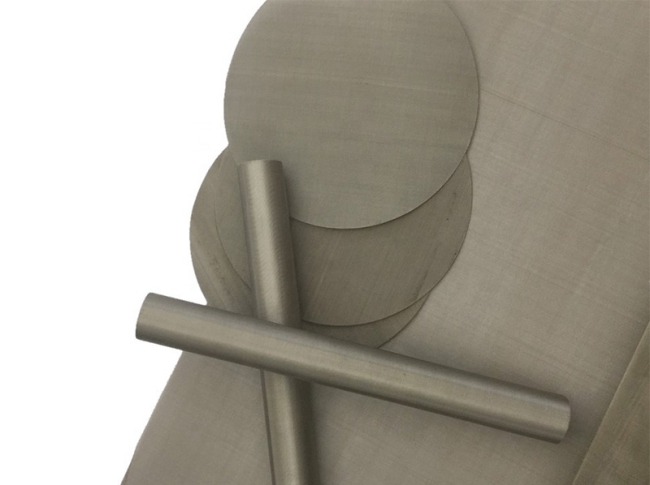

2. Selection of silkscreen The screen printing plate for glass printing is the same as the general screen printing plate. The glass screen printing plate uses synthetic fiber screen, stainless steel screen, and natural fiber screen. When printing general color materials, the above-mentioned screens are acceptable. Generally, cheap synthetic fiber screens are used; when used as gold and silver decoration, stainless steel screens cannot be selected. The specifications of the wire mesh are generally 270 to 300 mesh.

3. The selection of the screen frame Currently, the more regular and less deformed screen frame is an aluminum alloy frame, and its size should be larger than the pattern. The specific size should be 70~100mm from the outer edge of the pattern to the screen frame. In addition, the strength of the frame is very important. The key is that the horizontal rigidity is sufficient.

The above information is provided by glass printing mesh supplier.